Polyacrylamide Production Process

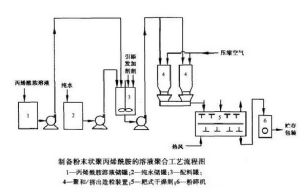

The production process of polyacrylamide includes batching, polymerization, granulation, drying, cooling, crushing and packaging. The raw materials enter the batching kettle through the pipeline, add the corresponding additives and mix evenly, cool down to 0-5°C, send the raw materials to the polymerization kettle to remove oxygen through nitrogen, and the oxygen content is reduced to about 1%, and then add the initiator to carry out polymerization After polymerization, the rubber blocks are chopped, sent to the granulator by the conveyor for granulation, the granulated rubber particles are sent to the drying bed for drying, and the dried materials are sent to the crushing and screening system for crushing, and the crushed materials enter The packaging system performs packaging to form finished products.

There are two steps in the production process of polyacrylamide

Monomer Production

The production of acrylamide monomer is based on acrylonitrile as raw material, which is hydrated under the action of a catalyst to form a crude product of acrylamide monomer. After flash evaporation and refining, a refined acrylamide monomer is obtained. This monomer is the production of polyacrylamide raw material.

Acrylonitrile + (water catalyst/water) → synthesis → crude acrylamide → flash evaporation → refining → refined acrylamide.

Polymer Production

Polyacrylamide is produced with acrylamide aqueous solution as raw material. Under the action of an initiator, a polymerization reaction is carried out. After the reaction is completed, the polyacrylamide rubber blocks are cut, granulated, dried, and pulverized to finally obtain polyacrylamide. Acrylamide products. The key process is the polymerization reaction. In the subsequent treatment process, attention should be paid to mechanical cooling, thermal degradation and crosslinking, so as to ensure the relative molecular weight and water solubility of polyacrylamide.

Acrylamide + water (initiator/polymerization) → polyacrylamide block → granulation → drying → crushing → polyacrylamide products

I hope the above polyacrylamide information can be helpful to you. If you want to know more about pam, you can contact our factory at any time.

The factory has been established for 23 years, with an annual output of more than 5,000 tons of pam. It has complete varieties, stable and reliable quality, and timely supply. There is no middleman in the first-level supply. The price is better and the after-sales service is perfect. The products sell well in the national and international markets.

Technical consultation: +86 15837197751