Cationic Polyacrylamide Flocculant

Cationic polyacrylamide flocculant, cationic flocculant has a strong flocculation and sedimentation effect on suspended particles in the aqueous medium.

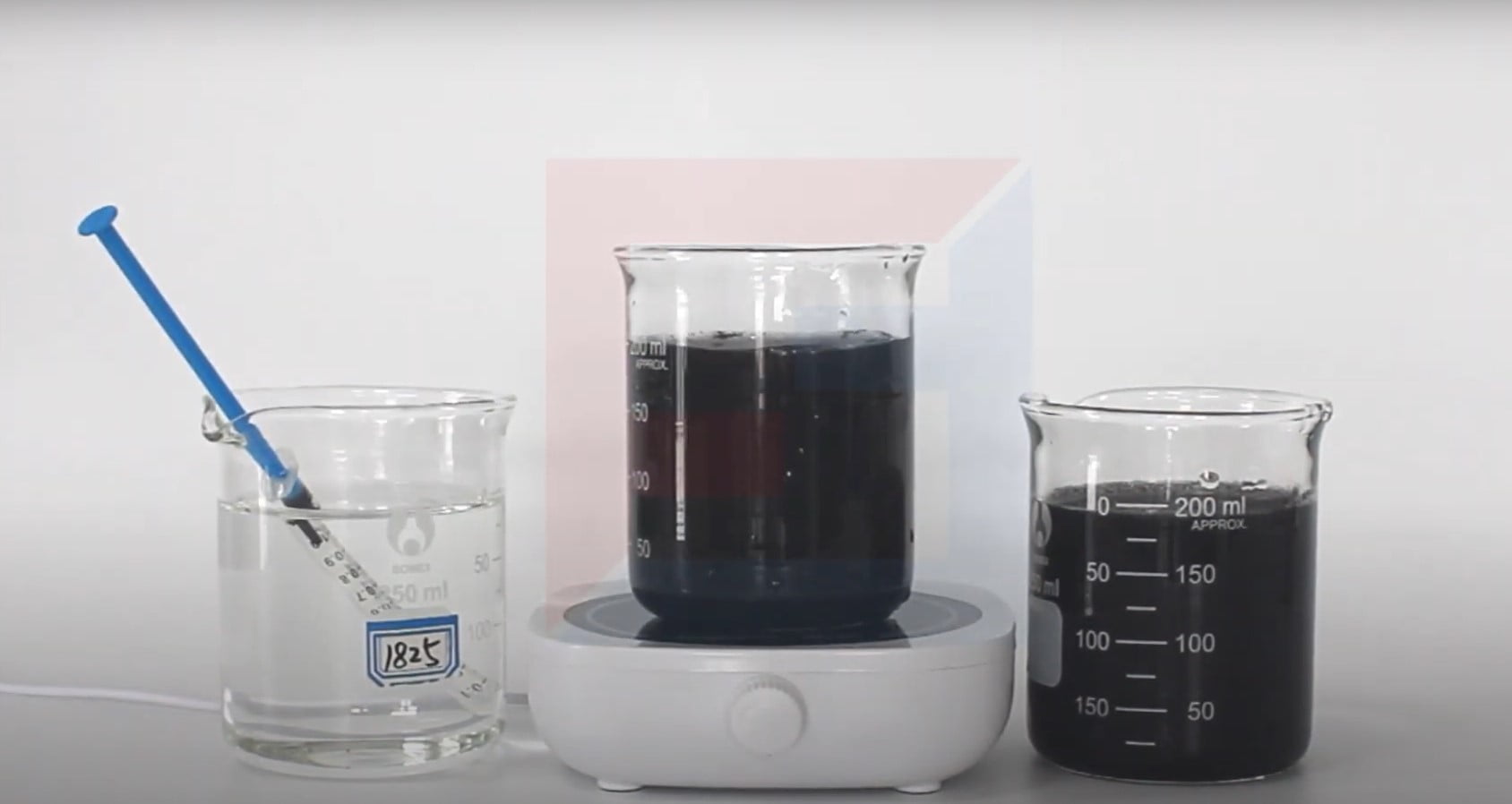

Cationic polyacrylamide flocculant sedimentation

1. Negatively charged suspended particles lose their dispersion stability through electrical neutralization.

2. Through the "bridging" effect, suspended particles are aggregated into large particles to accelerate sedimentation. The aggregates formed are tighter and firmer than the flocculation aggregates formed by inorganic flocculants because they are conducive to mechanical dehydration.

3. React with negatively charged dissolved matter to produce insoluble matter precipitation.

Characteristics of cationic polyacrylamide flocculant

1. It has good water solubility and can be completely dissolved in cold water.

2. Adding a small amount of cationic flocculant products can achieve greater flocculation effect. Generally, only 0.01-10ppm (0.01-10g/m³) is needed to exert its effect.

3. Use cationic flocculants and inorganic flocculants (polymerized ferric sulfate, polyaluminum chloride, iron salts, etc.) at the same time to achieve greater effects.