What Should You Pay Attention to When Using Polyacrylamide?

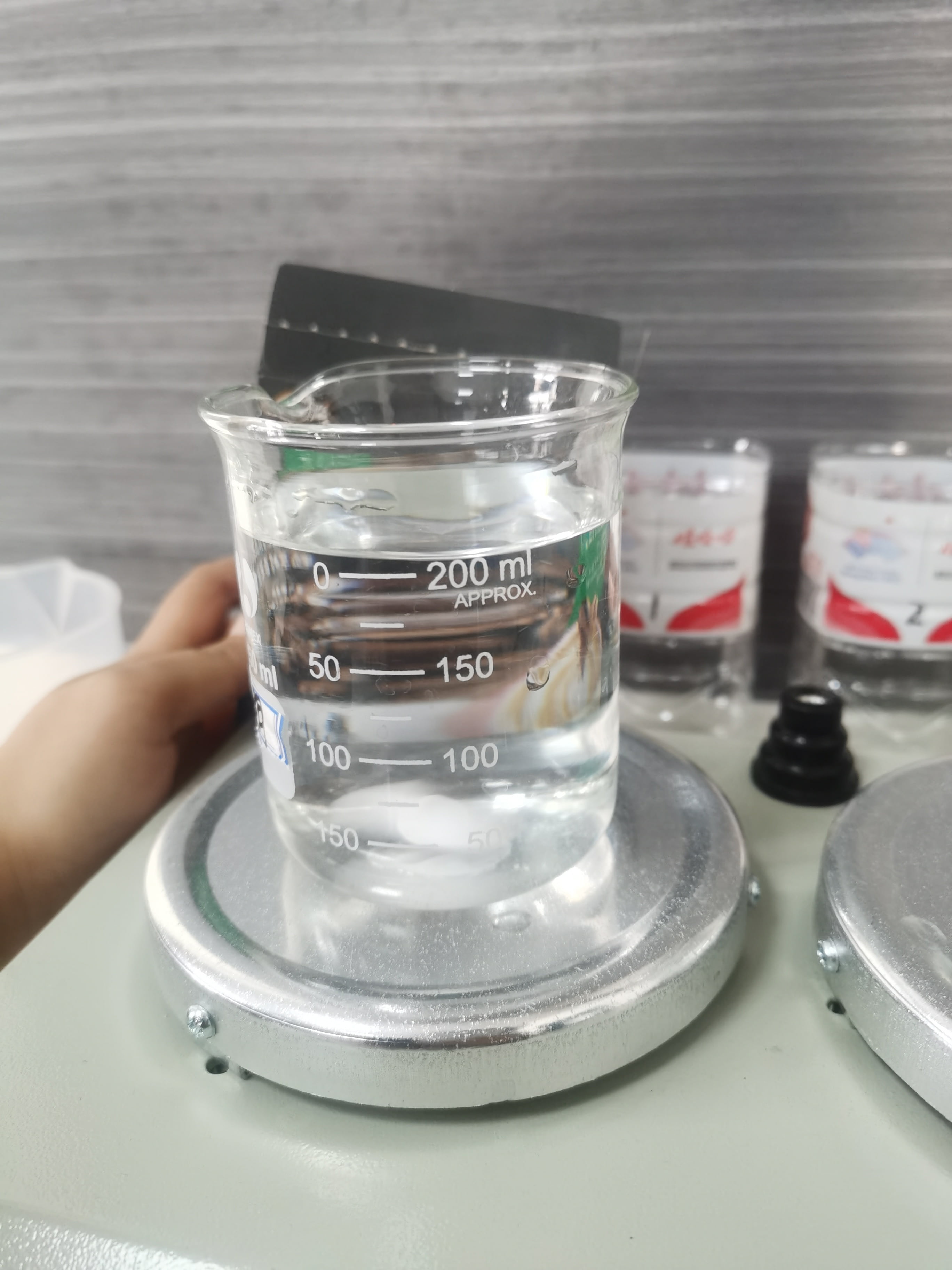

What should you pay attention to when using polyacrylamide? Solid polyacrylamide usually needs to be prepared into a liquid before use. If the method is improper or the dissolving device is inappropriate during the preparation process, it will cause product degradation.

For example, using gray water or water with a pH exceeding the standard as a solution, and using iron containers. The above two situations are "fatal" for polyacrylamide products, and the consequence is that the prepared pharmaceuticals are not ready for any use. value.

Furthermore, some customers use higher temperature water for preparation. Although it will speed up the dissolution of polyacrylamide, it will also cause great damage to the performance of polyacrylamide. It is generally recommended to use tap water at room temperature, and the water temperature should not exceed 40°C.

If the prepared medicine is not used immediately, after more than 24 hours, the degree of degradation will also be different due to different types of polyacrylamide ions. Pure water can be used to store it for a longer period of time, but many usage sites basically do not have such conditions. . In actual use, there are many reasons for product degradation or poor performance.

First, let’s talk about the configuration: It is generally recommended to use tap water when preparing. The temperature of tap water is generally moderate. There will be differences due to seasonal differences or different regions, but it will not affect the dissolution of polyacrylamide products.

The prepared polyacrylamide solution does not have an upper limit for use in any high-temperature environment. When the temperature reaches a certain limit, the product will also degrade and fail. Usually under natural conditions, the use effect will not be affected as long as it is not left for a long time. Even in the face of high temperatures in various places, the "BBQ mode" will not cause polyacrylamide degradation.

If it is used in wastewater or other solutions above 60°C, the amide group of polyacrylamide will become less active at high temperatures, which will cause a linear decline in application performance. As the temperature increases, polyacrylamide degrades more and more. It is becoming increasingly obvious that when the high temperature reaches a certain peak, polyacrylamide will completely lose its product characteristics and become ineffective. Therefore, when generally configuring polyacrylamide, it must be quantitatively configured and stored correctly, otherwise the sewage treatment effect will not be achieved.